At Grouphug Solar I help to create sustainable manufacturing processes. We reduce labor and environmental impact by using laser cut bamboo cut from sustainable forests. We also designed the product to be repairable and have workshops to help customers learn more about solar energy, technology, and design.

At Grant Blvd we utilized deadstock and reclaimed fabrics to create fresh designs that are one of a kind or small-batch. We cut fabrics with the least waste possible and use scraps when we can. We used the power of limits in fabric sources to drive our designs to be more innovative. We also screen printed on clothing from the thrift store and used natural dyes.

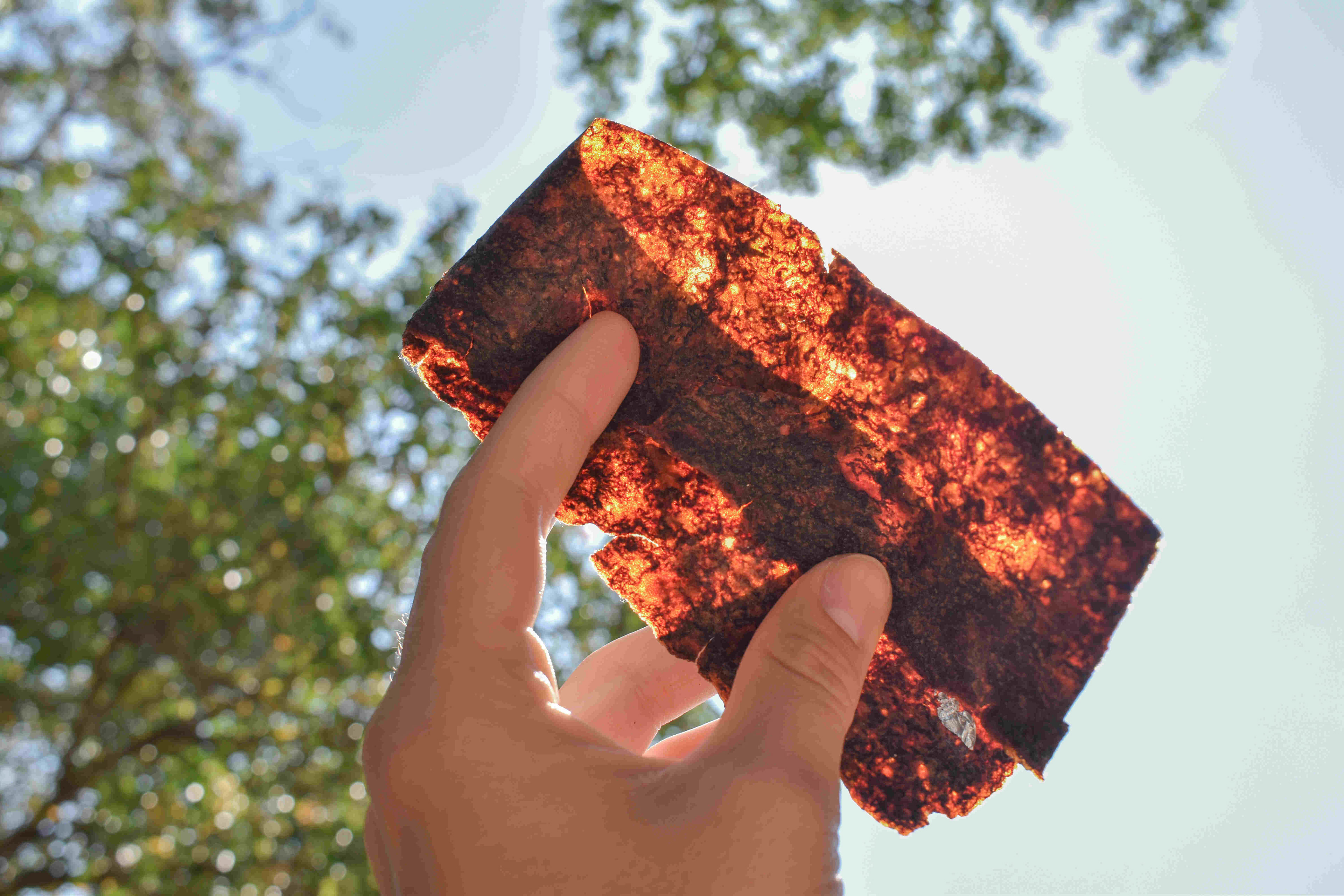

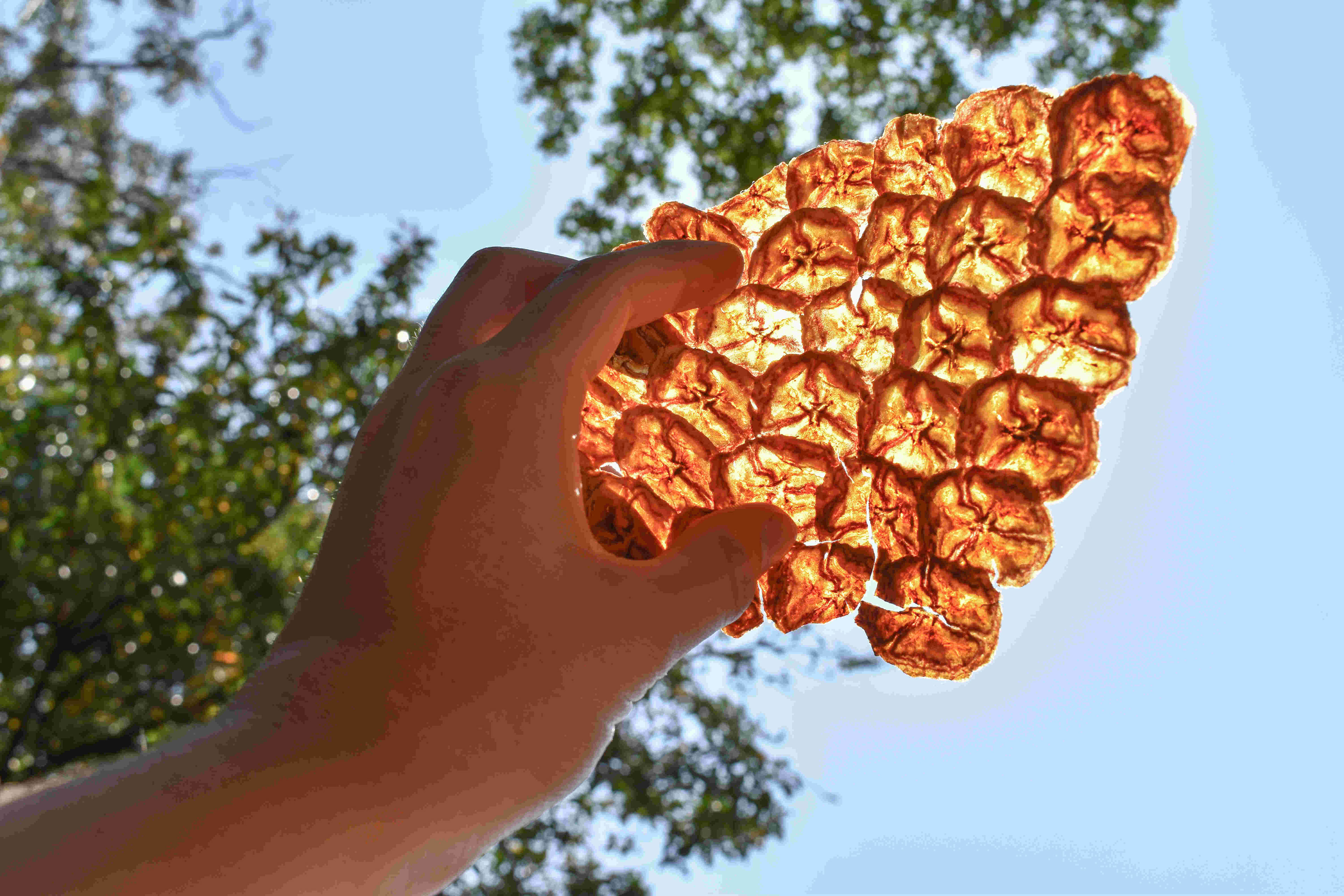

I designed a new lampshade material out of dehydrated bananas. I utilized the sun and other natural elements to aid in my process, trying to keep as low of an impact as possible. This manufacturing method is small-batch but could be scaled with the proper implementation methods and machinery.